PHOTOVOLTAIC SOLAR PANELS EFFICIENCY

We often hear about the PHOTOVOLTAIC SOLAR PANELS EFFICIENCY and, with the same frequency, the efficiency is confused and assimilated to the quality of the panels themselves.

Let’s clarify one thing immediately: when we talk about efficiency , we are not talking about the quality of the modules, but about the performance per square meter. That is, the conversion efficiency is the space needed to create an amount of electric current.

PHOTOVOLTAIC SOLAR PANELS EFFICIENCY: what does it really indicate?

Technically, efficiency is the relationship between the output of electrical energy from the terminals of the photovoltaic panels and the energy of the solar radiation that reaches the surface of the module.

The standard value taken as a reference to indicate solar radiation is 1,000 watts / m²: if each square meter is “hit” with 1,000 watts of solar energy, how much of this energy actually becomes useful and usable electricity?

100% is not email, the most popular modules now reach a maximum of 20% conversion efficiency .

Not all photovoltaic modules are the same: there are different technologies for the realization of modules and different types of panels.

There are panels of monocrystalline silicon, those in polycrystalline silicon, panels with amorphous silicon, panels of CdTe (with cadmium dichloride ), generally with thin film and the most particular “with solar concentration” (which have the highest levels). of efficiency).

Each technology has different conversion efficiencies: monocrystalline silicon is generally the one that “converts” better (ie, using less space), similar performances are polycrystalline silicon panels.

The panels thin film , on the other hand, need larger to produce the same amount of energy the above (however, photovoltaic thin film has other advantages) surfaces.

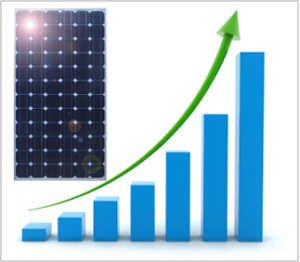

The conversion efficiency of photovoltaic technology, as research and development progresses, increases with the years. Already compared to a few years ago, we have photovoltaic panels in the market with greater efficiency and lower costs .

In 2011, the products in the market had an average conversion efficiency of between 7 and 15% . That is to say: at 1,000 watts “irradiated” in a square meter by the sun, a photovoltaic panel could, on average, transform between 7 and 15% in electricity.

This was the average efficiency of the photovoltaic panels in 2011:

- Monocrystalline silicon photovoltaic modules : 15.1%

- Polycrystalline silicon photovoltaic modules : 14.8%

- Photovoltaic modules CIS thin film (copper, indium, selenium): 12.3%

- Thin-film photovoltaic modules with cadmium dichloride (CdTe): 11.7%

- Amorphous silicon photovoltaic modules: 7%.

As mentioned, technology and research in the photovoltaic supply chain are taking their course in a sector that is about to mature.

Continuous improvements in processes and economies of scale bring gradual improvements in terms of cost-efficiency of photovoltaic panels: efficiencies increase gradually compared to lower costs.

This is the average efficiency of the photovoltaic panels marketed today in the market :

- Monocrystalline silicon photovoltaic panels: 17%

Some modules (eg Sunpower) also reach 20% . - Polycrystalline silicon photovoltaic panels: 16.5%.

- Thin film CIS photovoltaic panels (copper, indium, selenium): 15%

- Thin film photovoltaic panels with cadmium oxide (CdTe): 13.4%

- Amorphous silicon photovoltaic panels: 8.2%.

According to a study carried out by the Politecnico di Milano, less mature technologies, such as the CIS and CdTe modules, will present the broadest possible margins: panels with CIS technology will soon have an efficiency increase of 2-3. percentage points and modules in Tellmide of cadmium (CdTe) will have an increase in efficiency around 1-2%.

Energy efficiency of photovoltaic panels : we talk about solar yield taking into account only the technologies that currently exist in the market.

It is very difficult to talk about the efficiency of photovoltaic panels . With the same solar radiation to which the cells are exposed and at a constant temperature, the difference in efficiency (or efficiency ) is given by the materials used for the production of solar cells .

The efficiency or efficiency of a photovoltaic module is defined as the ratio expressed as a percentage of the energy captured and transformed into electricity, with respect to the total energy that affects the surface of the module itself .

The energy efficiency of photovoltaic panels is a parameter used to establish the performance and quality of the module described.

The efficiency of the photovoltaic panels , also defined as efficiency , is proportional to the ratio between the wattage supplied and the surface occupied under the same conditions (irradiation, solar radiation, temperatures, sunlight spectrum, spectral response …).

That said, it is natural to think that for the same amount of energy produced, a more efficient photovoltaic panel will occupy a smaller area.

The efficiency of a photovoltaic panel is closely related to the temperature and the materials used. For example, in reference to the temperature of 25 ° C of a solar cell, depending on the materials used, there will be different yields and different losses in relation to an increase in temperature.

The photovoltaic cells in crystalline silicon show complete efficiency at a temperature of 25 ° C, but yield drops of 0.45% per degree Celsius of temperature increase.

The photovoltaic cells in Silicium , with a good solar irradiation, can easily reach 70 ° C, pity that at this temperature the loss of performance is about 25%.

The photovoltaic cells that suffer less from the effects of temperature are those with multiple union ( GaAs, Ge, InGaAs … ) that see losses of 0.05% for each degree centigrade of temperature increase.

Energy efficiency and photovoltaic panels, where are we?

Everything depends on the economic investment that we can face for the construction of the solar plant . The more the performance of the solar panels increases , the more complex the production process becomes, as well as the costs of the materials and the final price.

Some concentration collectors for terrestrial use, developed from the aerospace model , as well as some multiple union cells, can return a nominal efficiency that exceeds even 40%! Unfortunately, the energy efficiency values found in commonly sold solar panels are much lower.

- The high efficiency heterojunction modules achieve a record performance of 25.6%.

- Solar modules with monocrystalline silicon technology achieve average efficiencies of 21%.

- Solar modules with polycrystalline silicon technology offer an average performance of 16.7%.

- The oldest amorphous silicon modules offer an average yield of 8.5%.

Among the excellences we highlight some consumer technologies that reach a yield of 25.6%. The leader in the production of solar panels is Panasonic, which is establishing itself in the field of photovoltaic technology defined as “heterojunction”.

It is a hybrid solution that combines the best features of thin film (ability to produce energy without experiencing a temperature increase) and the good conversion efficiency of solar modules with monocrystalline silicon technology. With photovoltaic heterojunction technology .

We started talking about a hybrid photovoltaic cell, which combines the advantages of different semiconductor materials. Photovoltaic panels with heterojunction modules will be marketed in Europe at the end of the first quarter of 2016 by Panasonic itself.